COLOR COATED STEEL

BRIEF

Color Coated Steel is a kind of Coated & Painting Steels, which is made by using special steel substrates, after surface chemical pretreatment, coated with one or more layers of paints on the surface by roller coating method generally, and then baked and cooled, and finally output a kind of steel sheet product.

Since the product is coated with organic paints and usually has beautiful colors or patterns after it is produced, it is also called Organic Coated Steel, Color Coating Steel, Color Painting Steel or even Colored Steel or Color Steel.

The output products are usual in steel Coils shape, also could be provided in Sheets or Plates shapes, and could be further produced into other final using products by deep processing, which are also called Color Coated Steel Coils / Sheets / Plates, etc.

Such steel has no painting required in the subsequent production of various products, so it is also a kind of Pre-painted Steels or Pre-coated Steels.

Color Coated Steel, Colored Steel, Pre-painted Steels

FEATURES

Color Coated Steel is a new kind of steel material developing rapidly in recent 60 years all over the world. By using special steel substrates and coated in production line, the kind of output steel is composed of metal substrate, chemical conversion, coating, and organic painting, and has advantages of both organic polymer and steel plate.

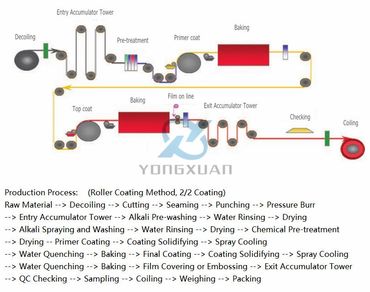

Color Coating Steel undergoes chemical pretreatment, initial coating, final coating, and other processes in a continuous production line. The coating is uniform, stable, ideal, and much better than the individual spray coating or brush painting of particular shaped metal parts.

Color Steel has excellent properties of decoration, shaping, and good corrosion resistance. The coating adhesion is good and will not be changed for a long period. With the advantages of replacing wood, high construction efficiency, energy conservation, preventing pollution and good economic effects, the Color Coated Steel already becomes an ideal material in the construction & building area and also being widely used in other industries.

APPLICATIONS

- Building Material:

Internal or external walls, doors, roofs, tiles, screens, ceilings, sandwich panels. Building projects material for structural constructions, rooms, houses, underground systems, drainage systems, ventilation systems, etc. Plants, pipes, elevators, and building accessories, etc.

- Engineering and Machinery:

Engineering projects and equipment, mill machinery, petrochemical equipment, mining machine, precast units, boilers, hardware, etc.

- Electrical and Lighting Equipment:

Refrigerators, washing machines, air conditioners, microwave ovens, toaster freezers, bread makers, switch cabinets, instrument cabinets, distributor boxes, motor boxes, fluorescent light covers, copy machines, etc.

- Packing and Storage Equipment:

Boxes, cans, containers, cabinets, tanks, vending machines, display windows, collection rooms, frames, brackets, shaped supports, warehouse, greenhouses, cold storages, silos, barrels, etc.

- Furniture and Office Equipment:

Household appliances, furniture panels, suite partitions, steel shutters, solar energy equipment, radiators, chests, drawers, desks, bookshelves, etc.

- Transportation Industries:

Car and train interiors, partitions, isolation fences, ships compartment plates, air purifiers, all kinds of piping, vessels equipped with all kinds of plates, oil purifier, distribution panels before the driver's seat, etc.

PRODUCTION

SUBSTRATES & TYPES

PPGF / PPGL

PPGF / PPGL

PPGF / PPGL

Prepainted Galfan / Galvalume Steels - PPGF/PPGL

Substrate: Galfan / Galvalume Steels (GF/GL)

PPEG

OTHERS

PPCR

Prepainted Electro Galvanized Steels - PPEG

Substrate: Electro Galvanized Steel (EG)

OTHERS

OTHERS

OTHERS

Other Prepainted Steels in more substrates, new functions, and new techniques.

COATING & PAINT

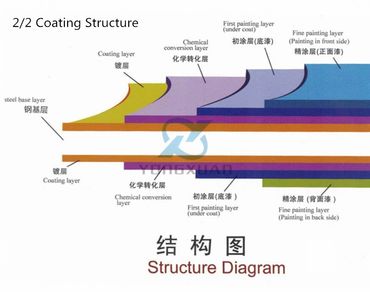

Coating Structure & Micro (Mainly):

2/2 (Front Double-coated / Back Double-coated). 2/1 (Front Double-coated / Back Single-coated).

3/3 (Front Triple-coated / Back Triple-coated). 1/1 (Front Single-coated / Back Single-coated).

Top: 10-50 μm, Back: 5-35 μm.

Paint Type (Mainly):

(PE) Polyester, (RMP) Regular Modified Polyester

Good adhesion, rich colors, wide range of molding and outdoor durability, medium chemical resistance, good hardness and flexibility, low cost; most widely used now.

(SMP) Silicon Modified Polyester

Good hardness, abrasion resistance and heat resistance, good external durability and powder resistance, normal gloss retention and flexibility, medium cost; mainly used as roofs, walls and structural parts for steel structures , steel windows, cars, etc.

(HDP) Hi-Durable Polyester

Excellent color retention and UV resistance, excellent outdoor durability and powder resistance, good paint adhesion, rich colors, excellent cost performance; mainly used as roofs, walls and structural parts for steel structures, building exterior project, etc.

(PVDF) Polyvinylidene Fluoride

Fluorocarbon Coatings, Excellent color retention and UV resistance, excellent outdoor durability and powder resistance, excellent solvent resistance, good formability and stain resistance, but low hardness, limited colors and high cost; mainly used for high requirement products.

(PVC) Polyvinyl Chloride

Excellent corrosion and wear resistance, good outdoor durability and film properties, good rheological properties, but difficult to control colors; mainly used in building panels, doors and windows, electrical cabinets, and packaging, etc.

(PU) Polyurethane

Good wear resistance and chemical resistance, good low temperature curability, high and low temperature resistance, high solid content, excellent overall performance; mainly used as bottom paint in equipment, transportation, machines, tools, etc.

(EP) Epoxide Resin / Araldite

Good hardness, strength, and softness, good wear resistance, high chemical stability, high cost effective; mainly used as bottom paint for primer painting, or for containers, panel lining, etc.

SHOWCASE

Color Coated Steels

PLAN

COPYRIGHT © 2017-2026 YONGXUAN - ALL RIGHTS RESERVED

COOKIE POLICY

THIS WEBSITE USES COOKIES. BY CONTINUING TO USE THIS SITE YOU ACCEPT OUR USE OF COOKIES.