TINPLATE

BRIEF

Tinplate is made by electro coating the pure tin on both sides of the cold rolled low carbon steel sheet or strip. It combines the strength and properties of the steel with the corrosion resistance, solderability and beautiful appearance of the tin. Tin has the advantages of corrosion resistance, color change resistance, oxidation resistance, non-toxicity, easy welding, soft and ductile.

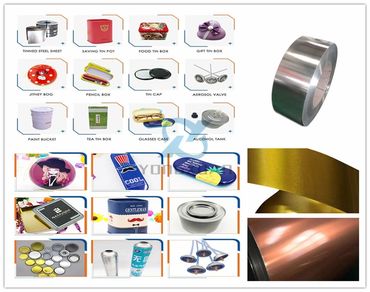

The biggest use of tinplate is for packaging, and it is an ideal material for this purpose. This is because tinplate is non-toxic, light weight, high strength, good corrosion resistance, and easy to process, solder and weld; in addition, it can provide very good printing surface. Tin coating has low melting point, lubricant properties, and gives the tinplate a beautiful appearance. Canned boxes made of tinplate can be easily shipped, stacked and stored. Tin plate is mainly used for food and beverage packaging, but also for packaging oil, grease, paint, powder, polishing agent, wax, chemicals and other products containers. Spray cans, caps, buckets, and all kinds of covers are also made of tinplate.

Tinplate sheets now have a wide range of products. Steel substrates can be coated with tin of different thicknesses. It can also produce a variety of finishing surface products to adapt to a variety of uses. Tinplate sheets are specially passivated to stabilize their surfaces and improve the adhesion of coatings. A thin film of oil is also attached to the surface to improve their storage, transportation and processing properties. Tinplate sheets can be used as substrates to produce color coated sheets, also can be printed pictures and patterns on the surfaces to output beautiful appearances for packing usages.

Tinplate Coils, Tinplate Sheets, Tinplate Products

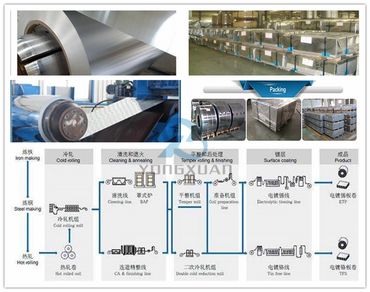

PRODUCTION

SHOWCASE

Color Coated Steels

SOLUTION

COPYRIGHT © 2017-2026 YONGXUAN - ALL RIGHTS RESERVED

COOKIE POLICY

THIS WEBSITE USES COOKIES. BY CONTINUING TO USE THIS SITE YOU ACCEPT OUR USE OF COOKIES.